Production

Our organisation comprises two cheese dairies where several thousand tonnes of cheese are prepared every year. In Katwoude and in Heerenveen, our Cheesemakers make no less than50 different age and herb cheeses from regular organic cow's, goat's and sheep's milk. This demands a lot from our Cheesemakers. Namely, they have to be able to switch quickly and effectively between the different cheese types.

At the Logistics department in Katwoude and Heerenveen, it is a daily challenge to organise all activities related to packaging, refining, maturing, storage and distribution of our cheeses as efficiently as possible so that our customers can get theirquality cheeses receive.

Our Technical Service employees repair mechanical, electrical, pneumatic, control and hydraulic failures and malfunctions on the process equipment in our factories. With their very broad technical expertise, they ensure that cheese production can continue at all times and their inventiveness ensures safer technical situations, a higher production capacity and the sustainability of our organisation.

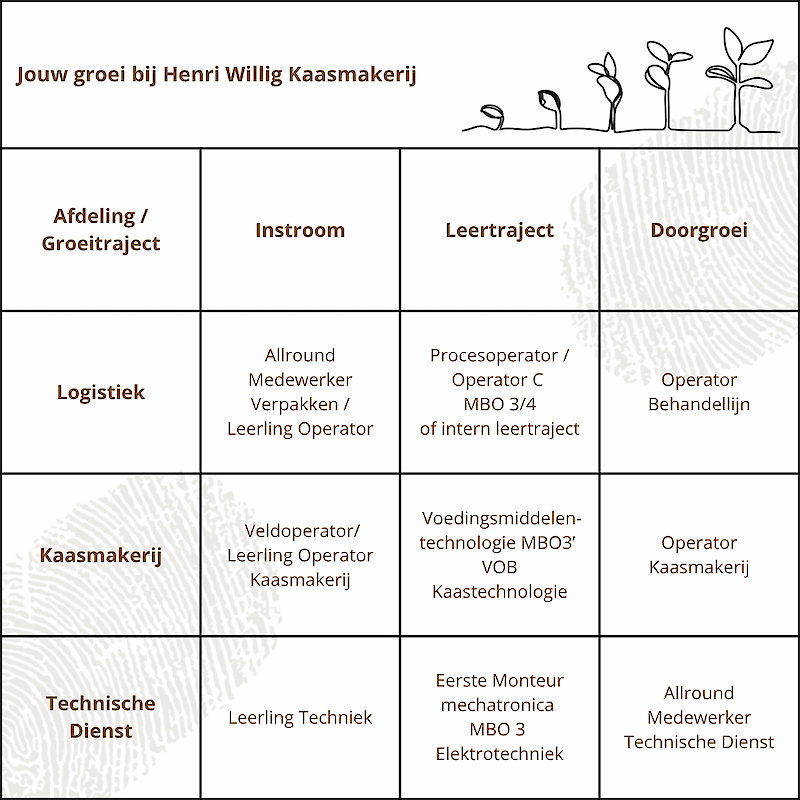

Your development within the Henri Willig Cheese factory

In our cheese factory, we believe in craftsmanship - and that starts with people. That is why we offer clear learning and career paths for the three specialist areas:

Logistics

Start as an all-round packaging employee and develop through a learning path into a handling line operator. You will work with modern techniques and contribute daily to an efficient cheese processing process.

Cheese factory

Start as a field operator or apprentice cheese maker. In our BBL programmes, you will learn everything about food, technology and cheese technology. You can progress to senior cheesemaker /1st operator and team leader.

Technical Service

As a technical apprentice you will learn mechatronics and technical skills. You will develop into an all-round technical service employee with responsibility for our innovative installations.

You can work and learn in BBL routes (working and learning at the same time) or via internal training courses. This allows you to grow as a starter into a professional specialist in a unique family business where quality and craftsmanship are key.

View the visual below for your personal growth path. Interested and/or questions? Contact us directly at werken@henriwillig.com or call/app Pieter Bakels on 06-34645684