Logistics

In the Logistics department in Katwoude and Heerenveen, it is a daily challenge to organise all activities related to the packaging, finishing, maturing, storage and distribution of our cheeses as efficiently as possible so that our customers receive theirquality cheeses receive.

In Heerenveen, our Business Office employees receive the orders from the sales office and use them to draw up the production planning for the cheese factory. As a result, our cheesemakers know when to produce which cheese variety (and in which quantity).

Based on the sales orders, the packing and storage planning is also immediately drawn up by the Works Office employees. As a result, our Logistics employees know exactly when which packaging and finishing activities need to take place.

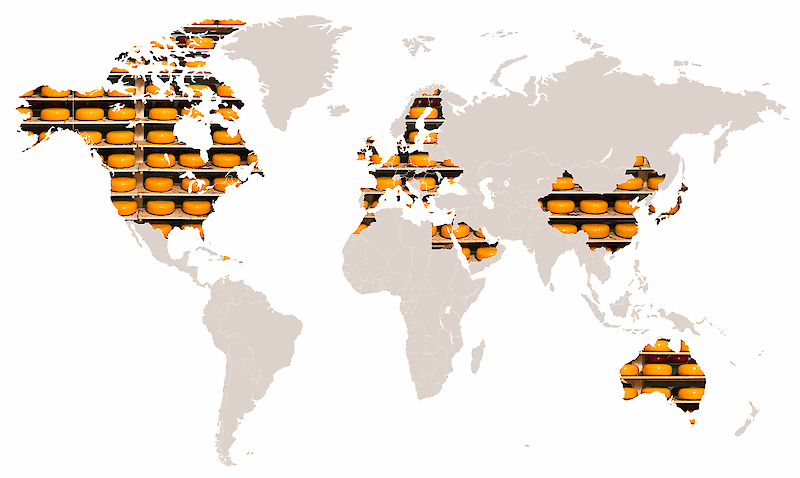

Finally, the Operations Office instructs the transporters on the basis of the order and production planning so that they can deliver our Dutch cheese specialities at the right time to our customers in more than 25 countries all over the world.

You can therefore rightly say that our Business Office employees use all their organisational and planning talents every day to form the beating heart of Kaasmakerij Henri Willig.

Our Logistics Department is responsible for carrying out all the activities that take place with the cheeses from the moment the Cheesemakers have pickled the cheeses. The logistics process thus starts at the brine bath. After brining, the cheeses are plasticised.

After the cheeses have reached the right age in the warehouse, the cheeses are labelled with the utmost precision with our own brand labels or the customer's labels. The cheeses are then paraffin-coated, if necessary, and packed and prepared for transport by our Logistics Staff.

Our Logistics Staff master all the activities described above and are therefore highly all-round trained. This not only ensures that the work is very versatile and varied, but also that our Logistics Employees have as much love and passion for cheese as the Cheesemakers. The Logistics Employees also put all their knowledge and energy into ensuring that consumers ultimately enjoy our distinctive cheese specialities.

In our cheese factory in Katwoude, almost the same processes take place as in Heerenveen. The difference is that in Katwoude cheese is made on a smaller scale and that the activities that in Heerenveen are handled by the Business Office are housed here in the other departments.

Another difference is that most of the cheeses are made for sale in our own shops and that we take care of transport to the relevant shops ourselves.